Disadvantages of printing system

Classification:

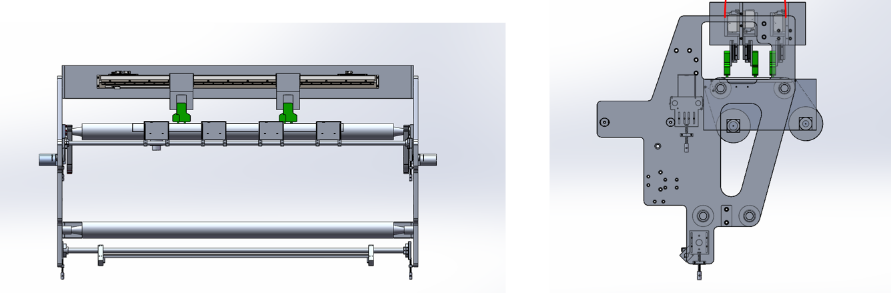

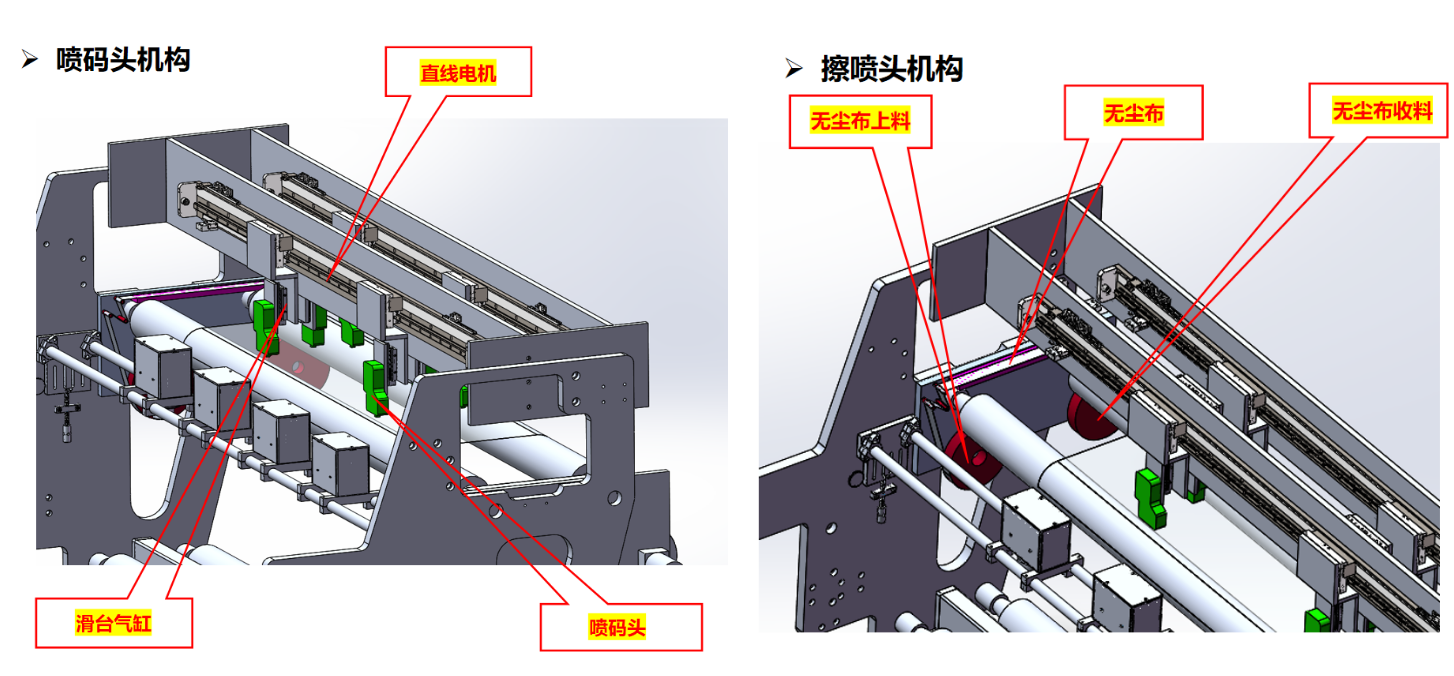

Polarizer Solution

Scheme Description

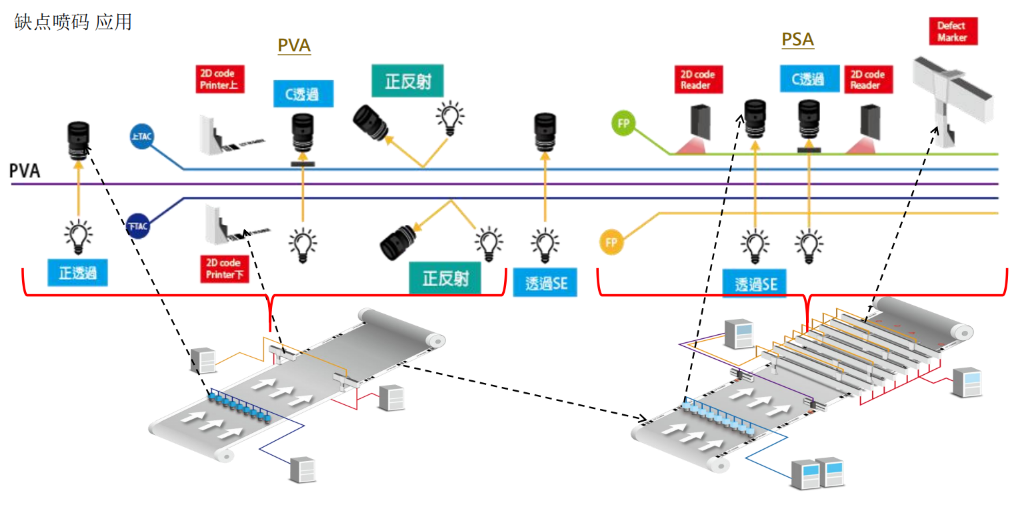

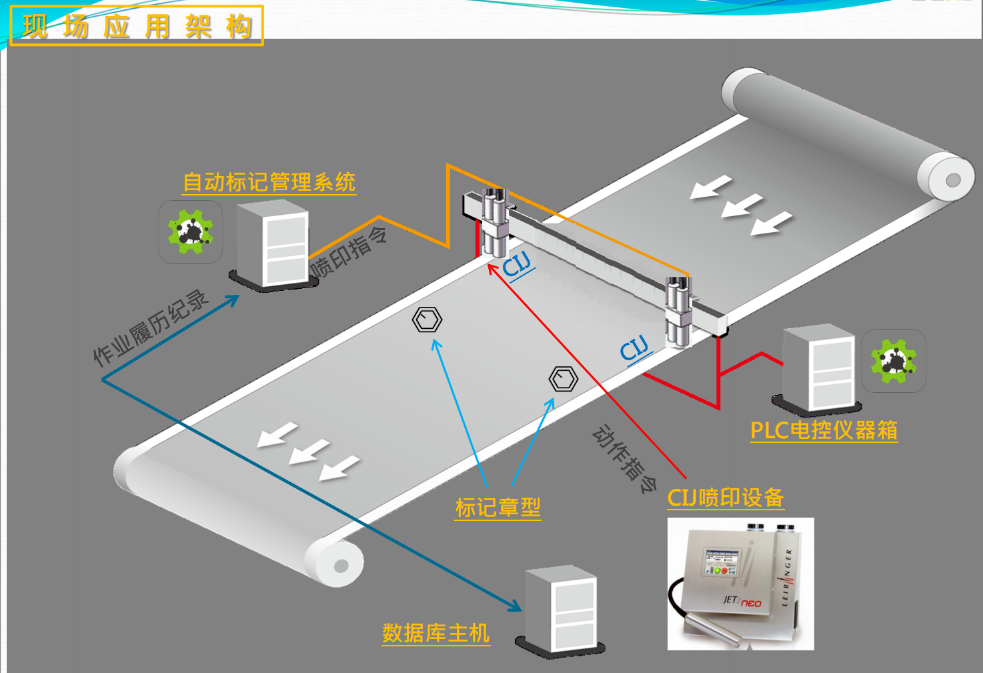

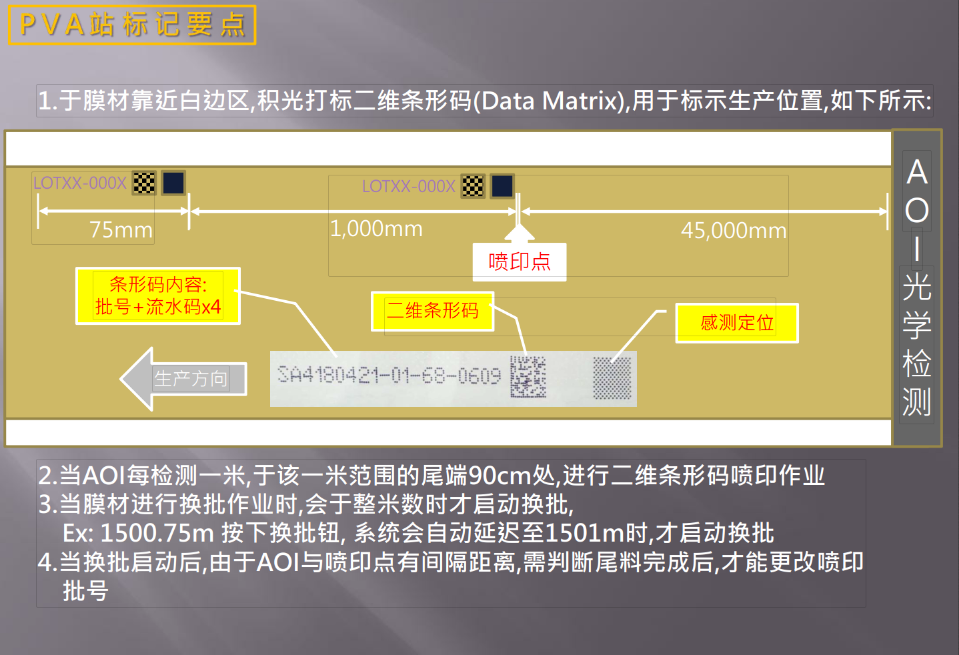

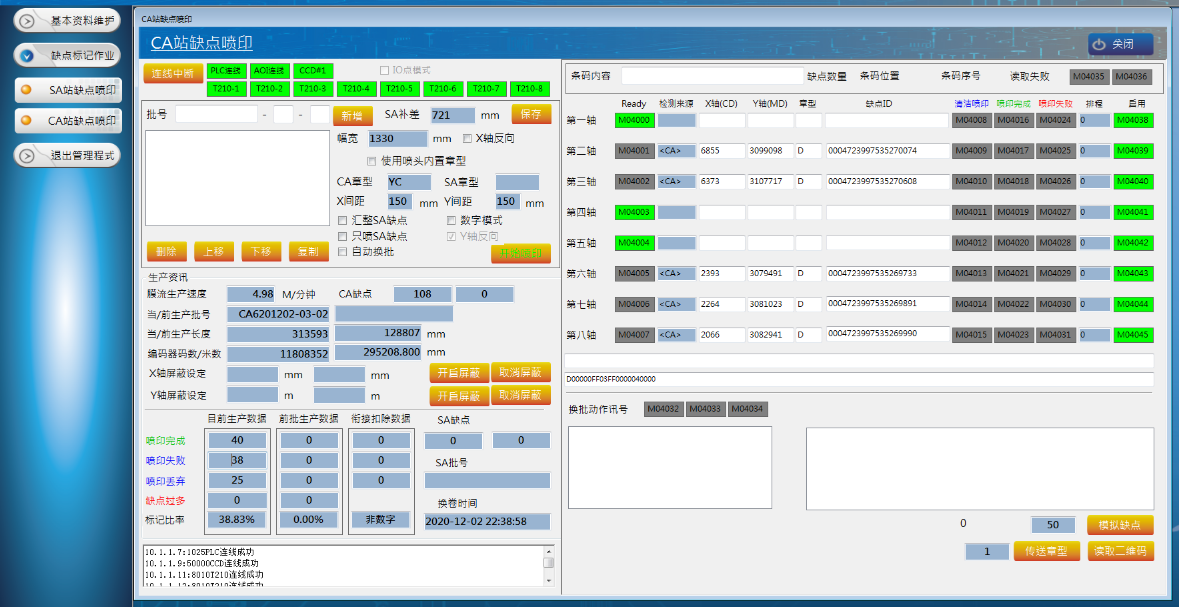

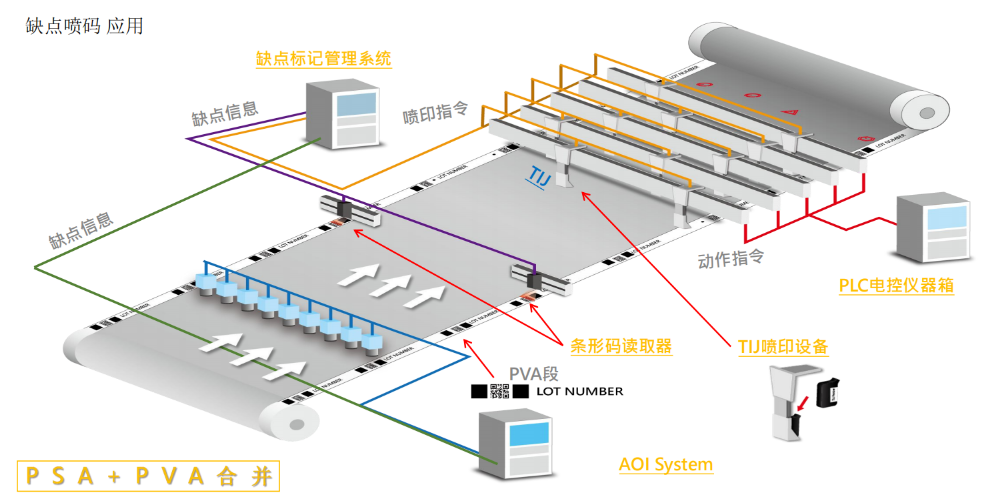

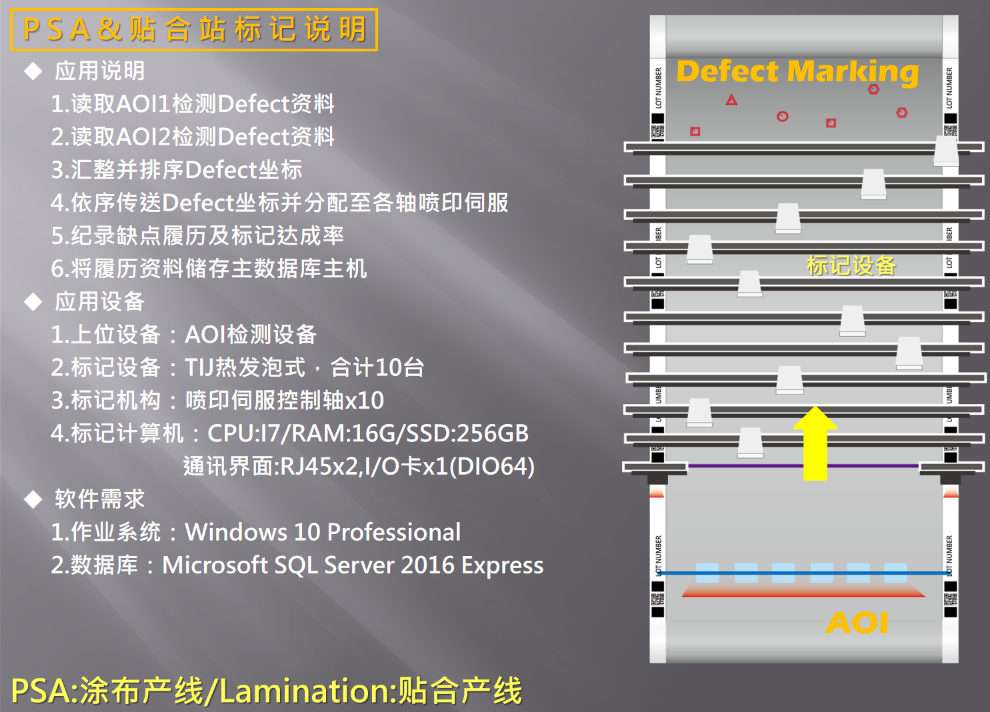

Defect marking management system Defect Marking System (DMS for short) can combine the defect data between PVA extension section and PSA coating section to integrate the defect data of the two sections of production operation, and then execute the defect marking operation. DMS system also has the storage and query functions of detection data and operation resume data, and the printing rate statistics of each production batch number. This scheme can not only improve the correctness of the spraying data, and it can effectively avoid human errors in operation, and further provide a complete marking resume.

Defect marking of polarizing plate will be combined with AOI detection equipment in production section, AOI detection data (Defect Position, Class, Severity) will be connected in series and code spraying equipment will be used for defect marking. This marking method can greatly improve the correctness of the defect marking.

Previous Page:

Next page:

Previous Page:

Next page: